Troubleshooting

Simple Fault Finding Procedure

The below guide is a quick and easy method to simply troubleshooting your Worcester Bosch Boiler, simply use the fault finding method below:

- Electrical Checks. Test the electrical circuits by checking for short circuits, continuity (earth) and resistance (to earth). Ensure system has appropriate electrical polarity.

- For Electrical 230V Supply. Inspect the boiler unit to ensure that the supply voltage is 230 V.

- For Gas Supply. Ensure the boiler has a gas supply. Check that it has been purged.

Warning Warning: Ensure only qualified CORGI registered contractors do these checks, it is illegal and danergous if you conduct your own gas checks!

- Heating system Filling. Check the boiler is full of water and pressurised to 1-1.5 BAR. Incorrectly filled boiler will reduce your efficiency.

- Control. Ensure main switch is set to ‘on’

- Temperature. ensure your heating temperature is set to the maximum setting.

- External Controls. Ensure that the controls circuit thermostat is calling for heat.

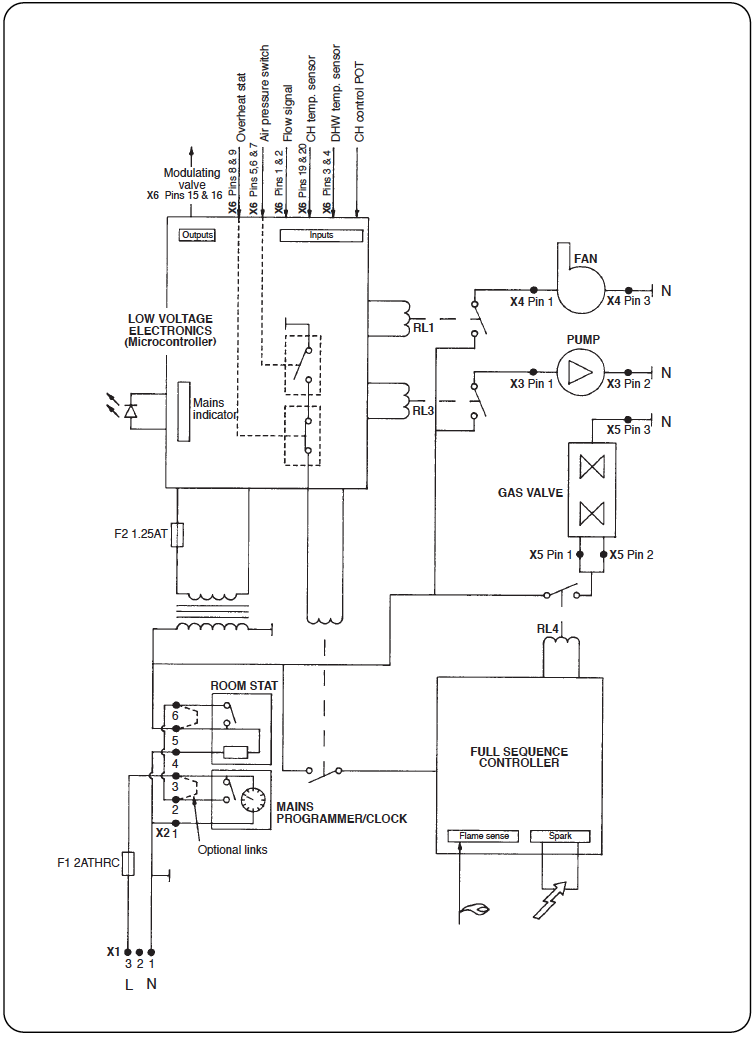

24i RSF Fault Finding

Follow the troubleshooting chart below to trace your 24i RSF issue and identify your boiler’s diagnosis. You will then be able to find the a suitable replacement part and fix your boiler.

Circuit Diagram

General Faults

PCB Faults

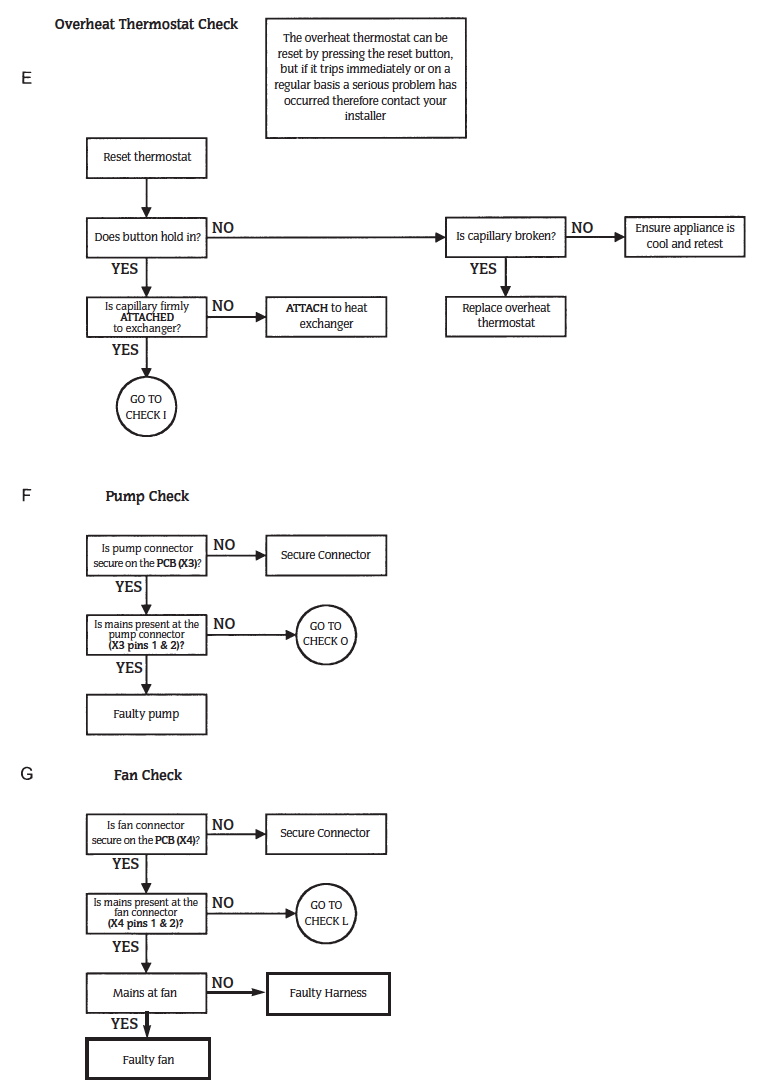

Thermostats, Pump and Fan Faults

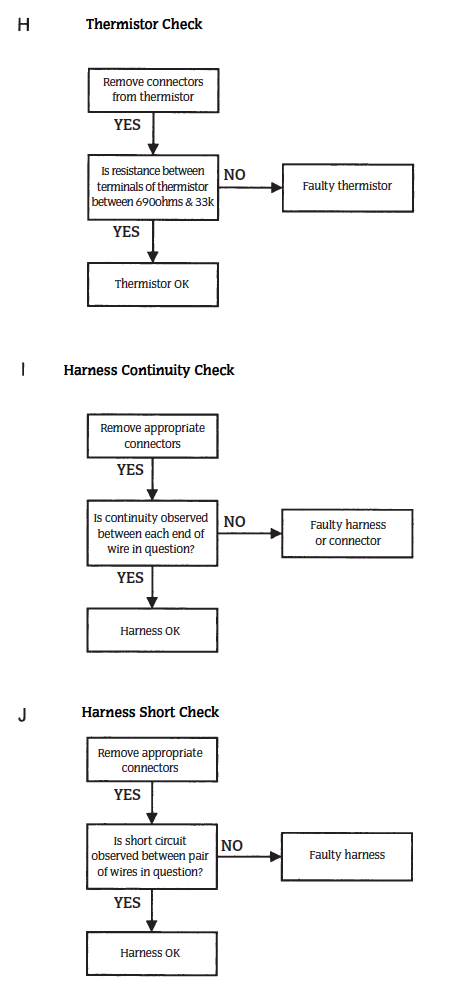

Thermistor, Hardness Continuity and Short Faults

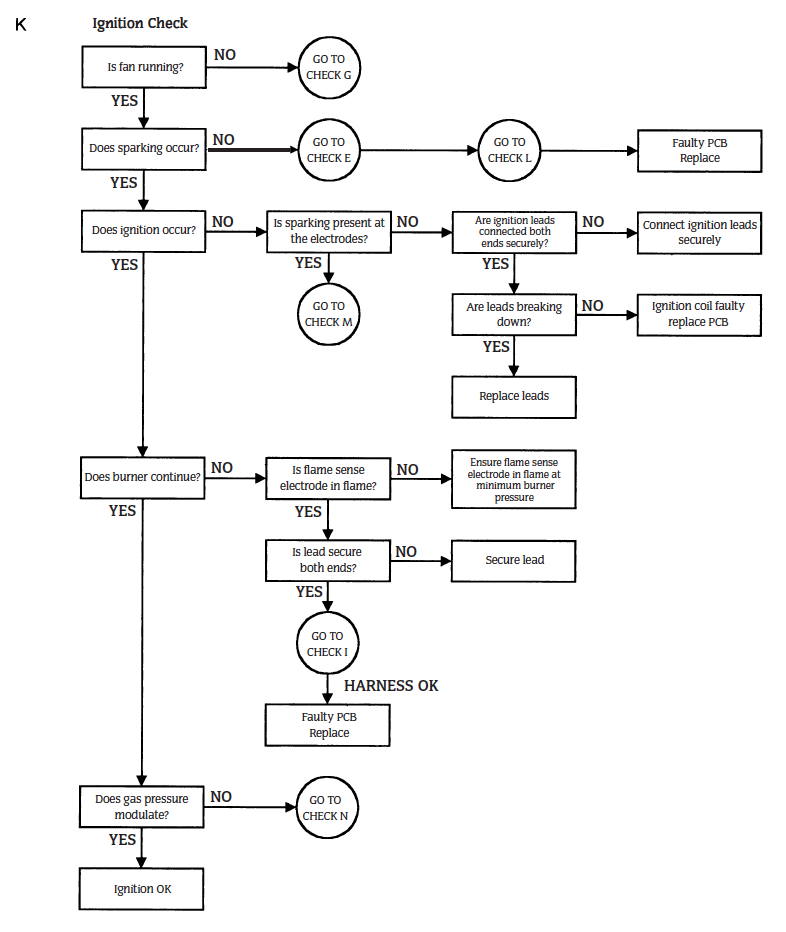

Ignition Faults

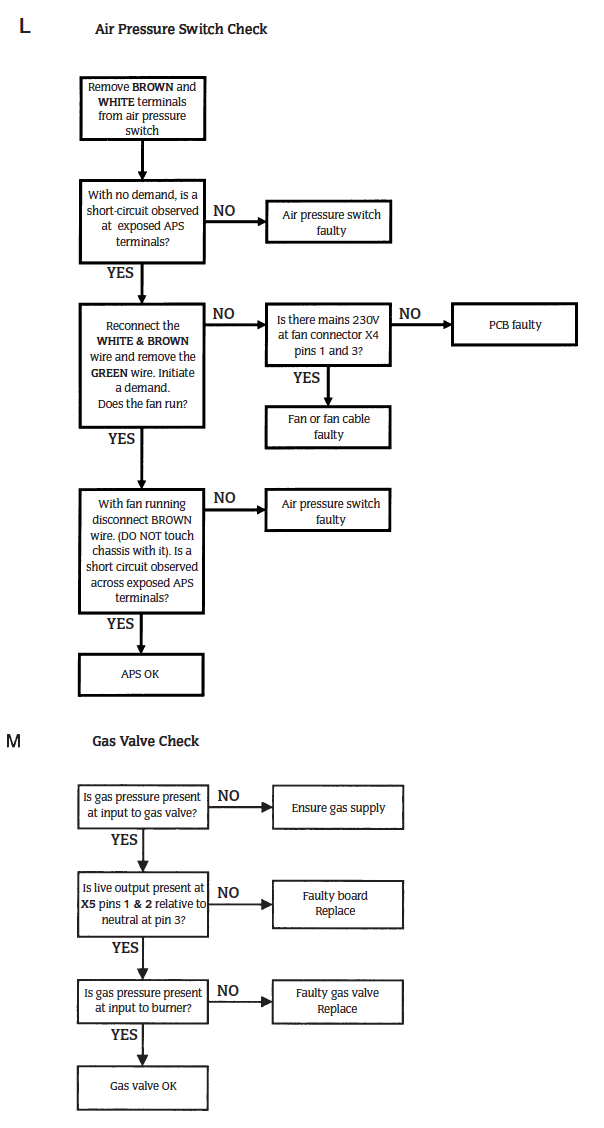

Air Pressure Switch and Gas Valve Faults

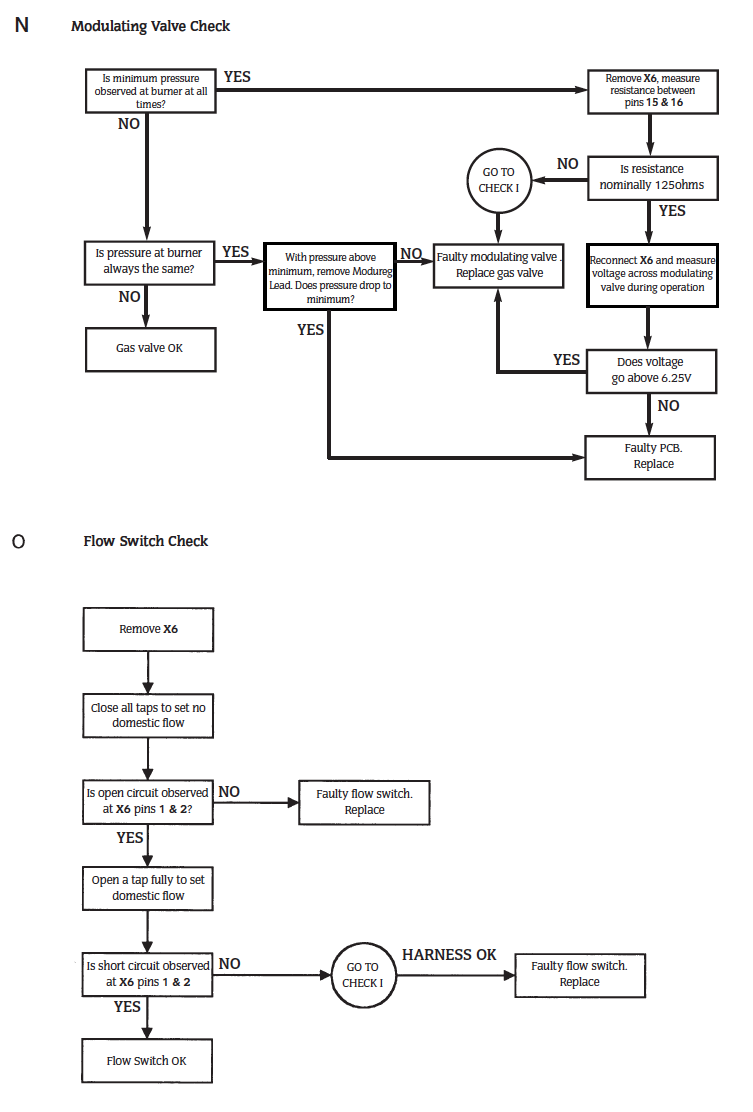

Modulating Valve and Flow Switch Faults

Worcester Bosch Bi and SBi Troubleshooting

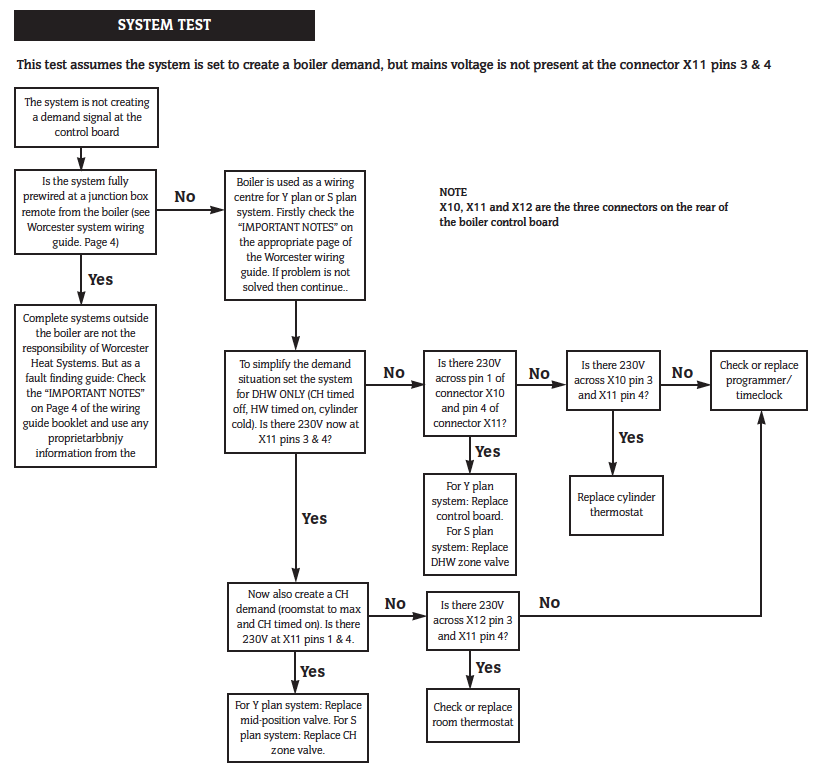

Conduct the following tests below to help fault find the specific issue you are experiencing with your Worcester Bi and SBi Boiler models. You can check the system for demand, indication or conduct a system test.

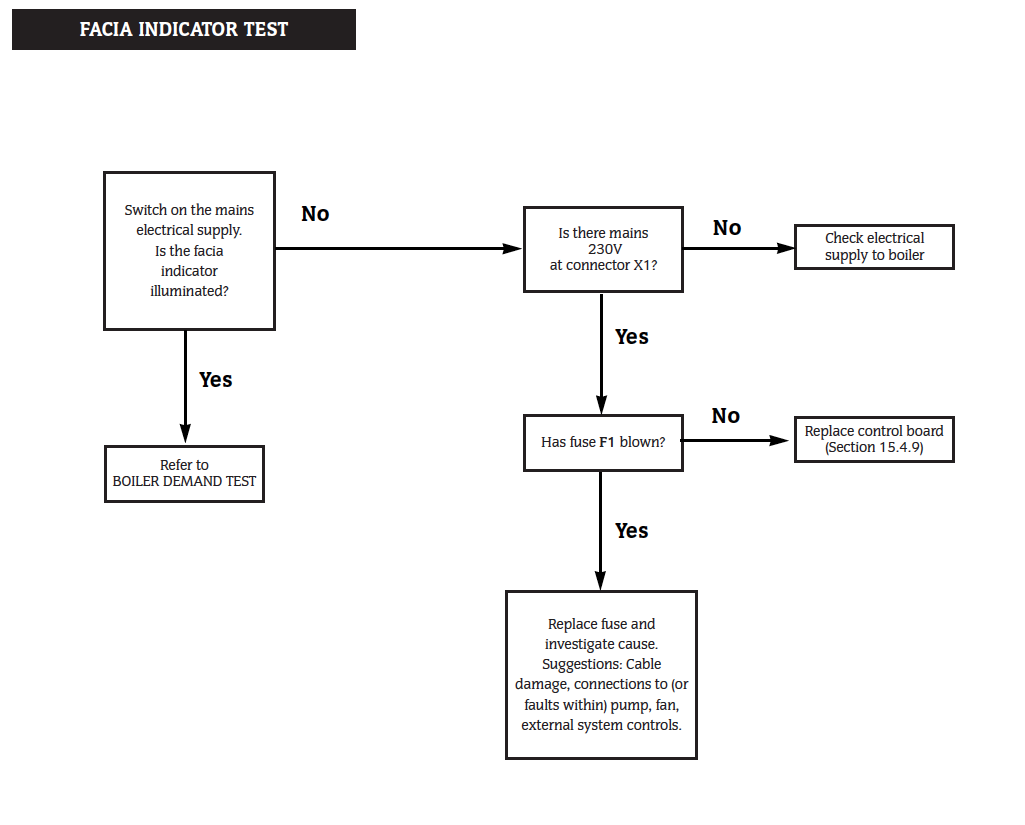

Facia Indicator Test

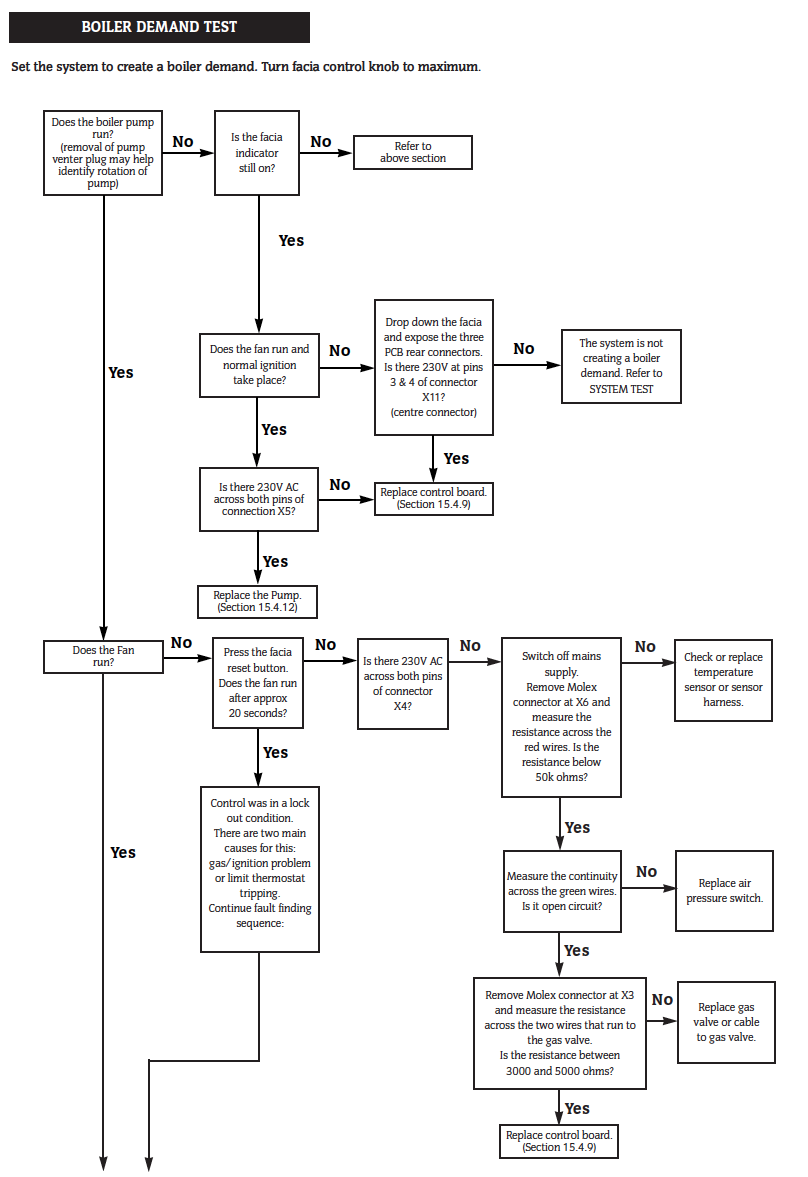

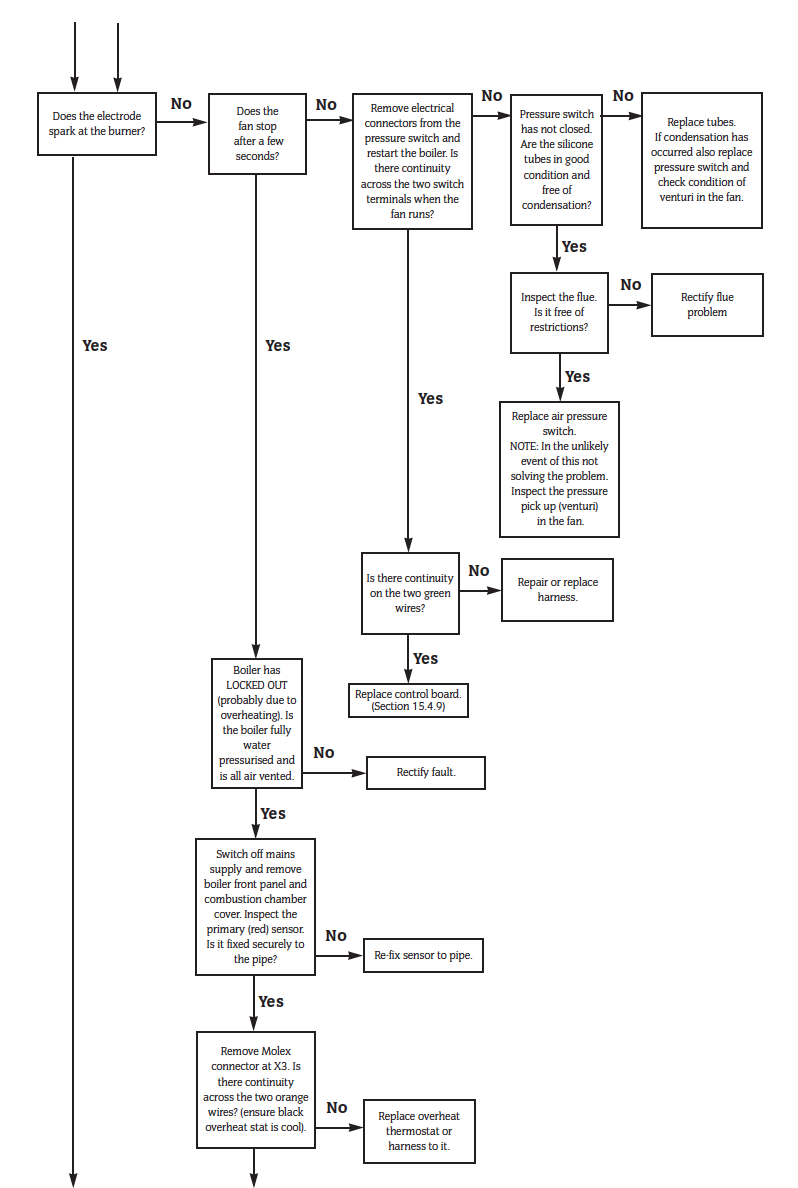

Boiler Demand Test

System Test

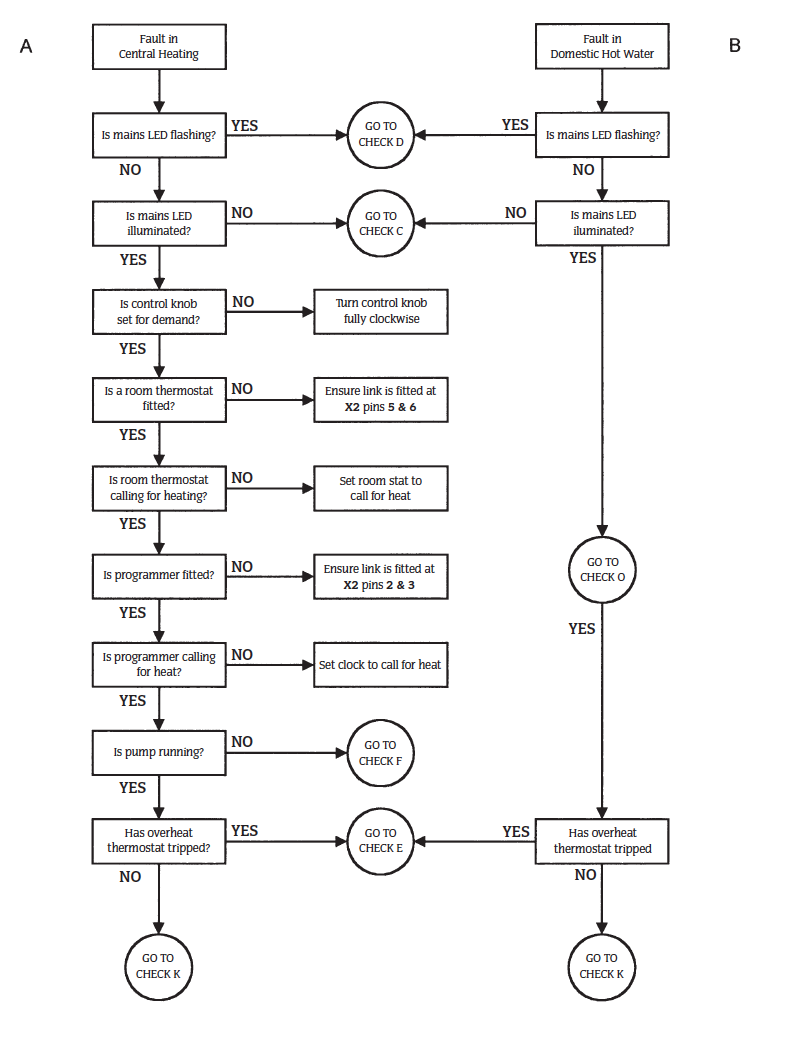

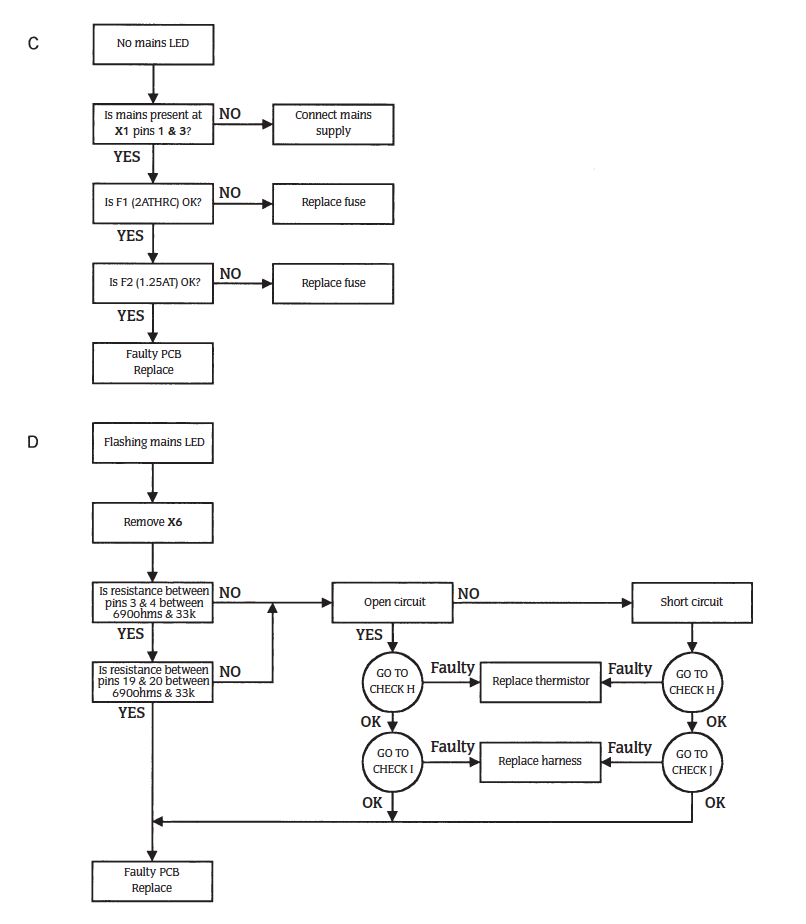

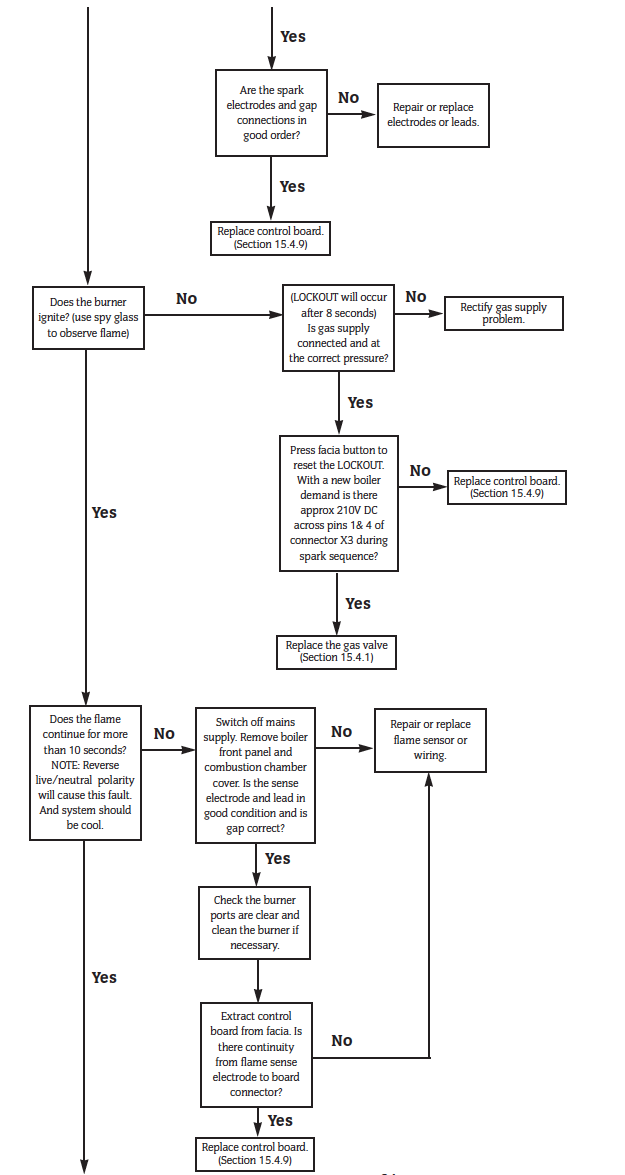

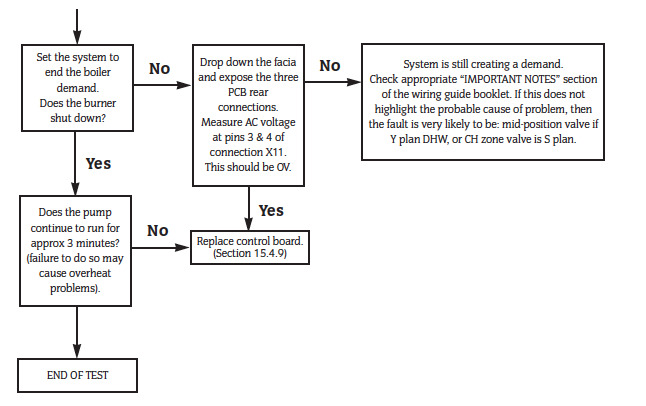

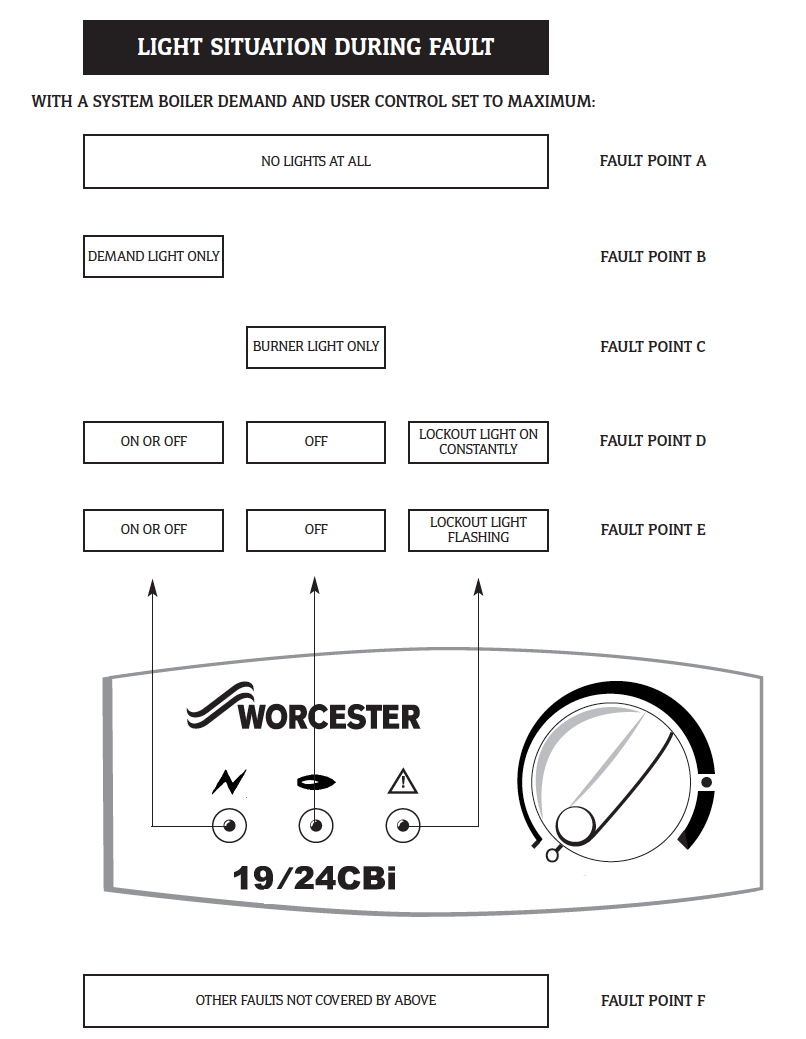

Worcester Bosch CBi

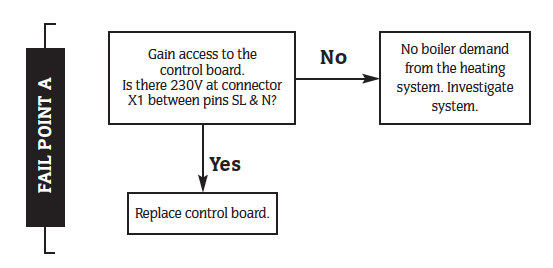

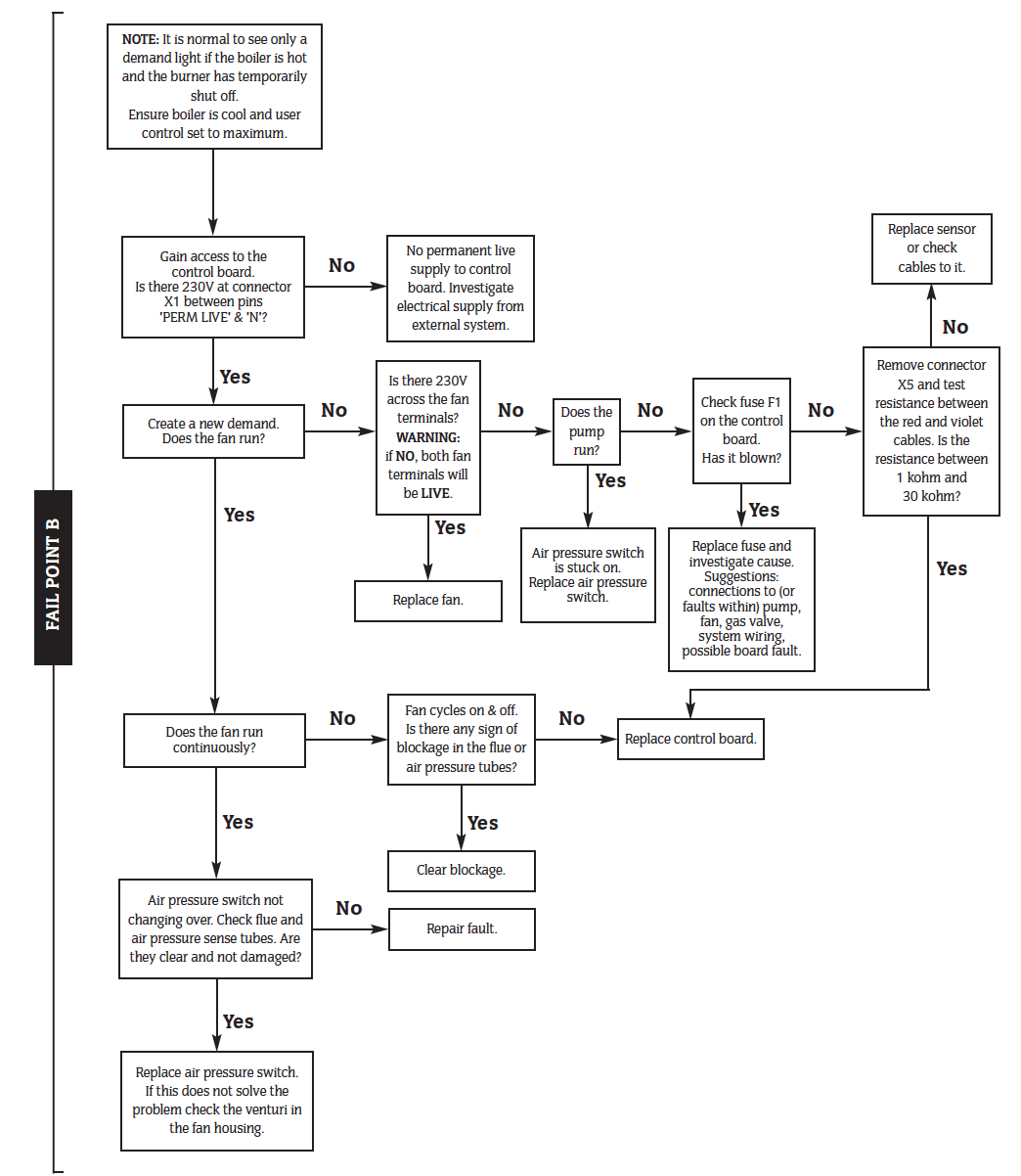

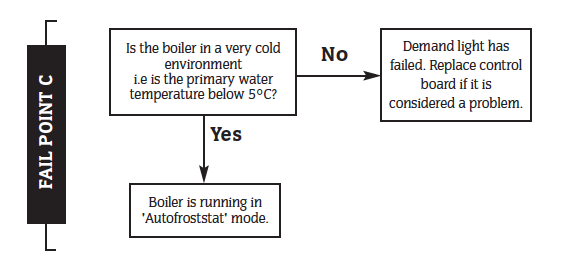

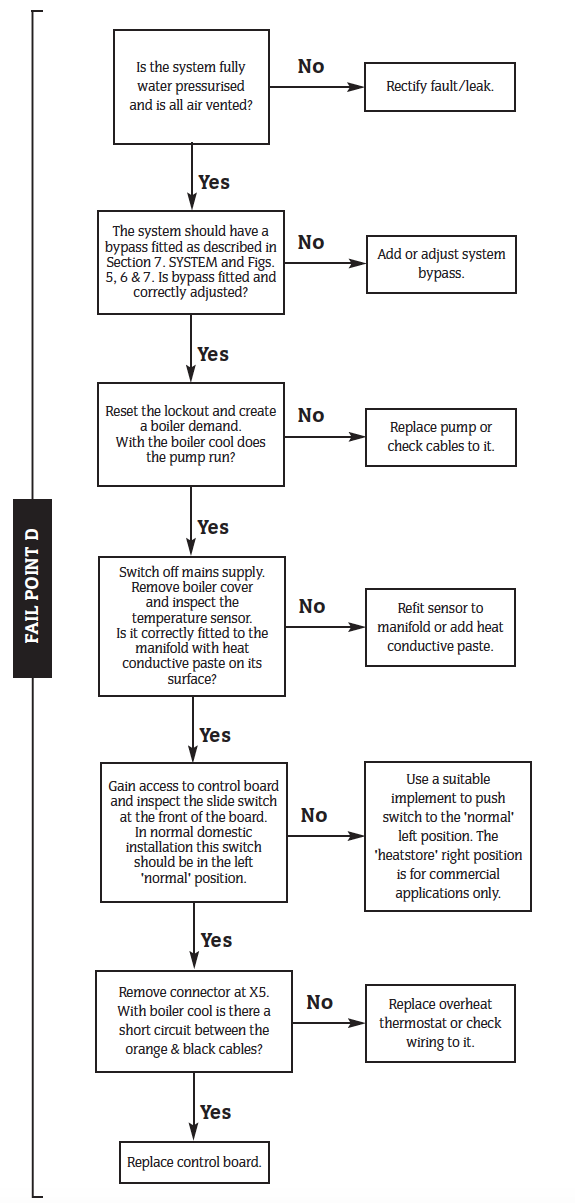

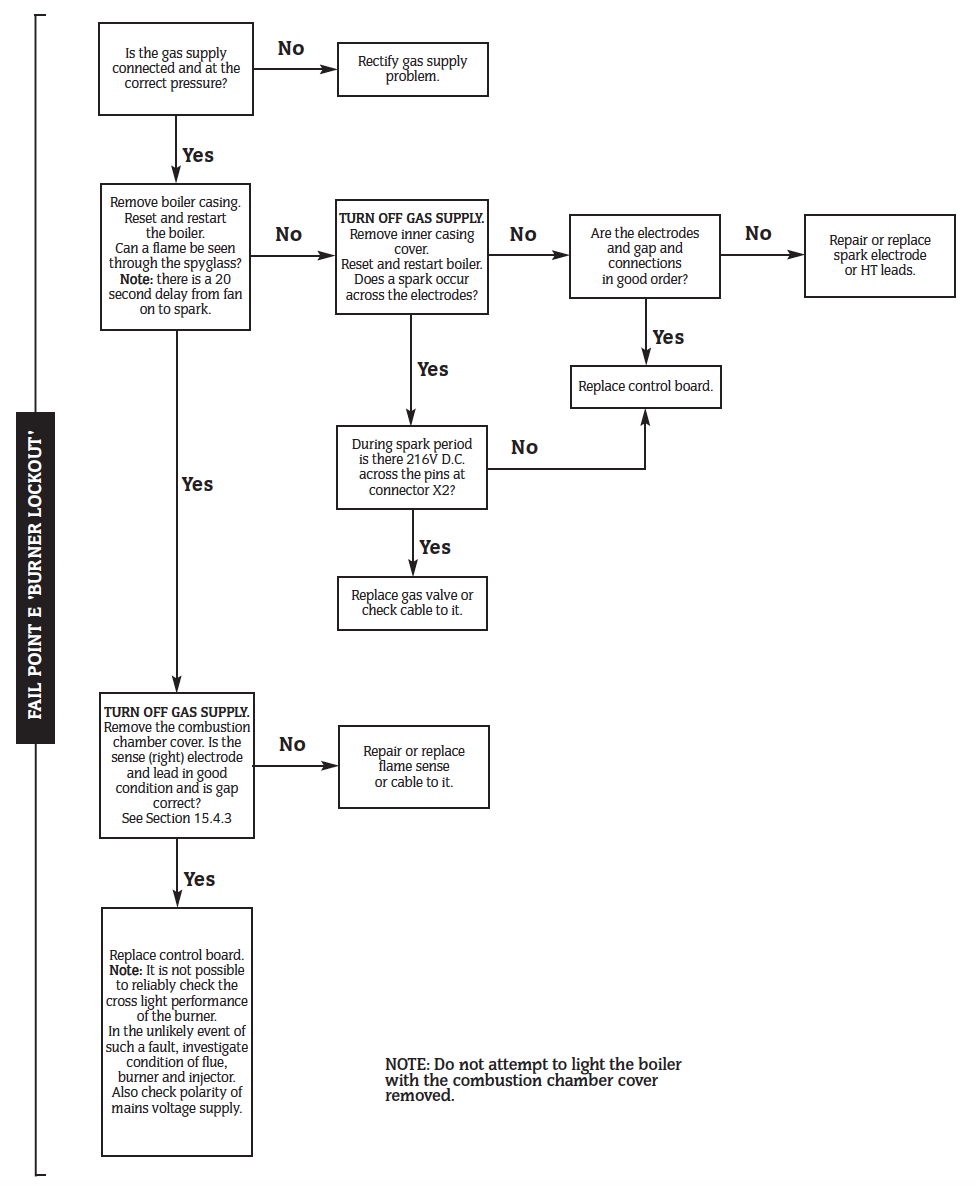

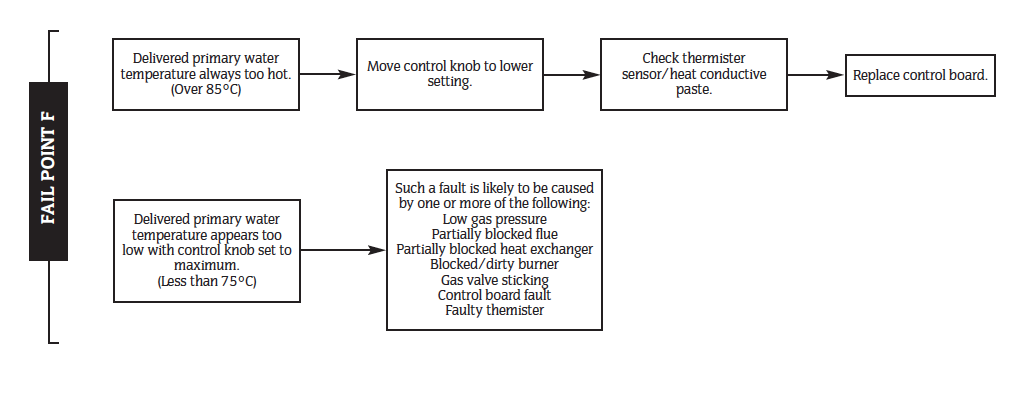

Use the troubleshooting table or fault finding flowcharts below to identify your Worcester CBi fault and troubleshoot either a solution or replacement part.

CBI Fault Lights

CBi Fault Finding Chart

Worcester Bosch CDi

The Worcester Bosch fault finding table below will help you diagnose your boiler’s fault and help you take the next decision in fixing the issue. You may want to then buy a replacement part of get a service engineer in to fix the issue.

CDi Troubleshooting Table

| Play Code | Description | Remedy |

|---|---|---|

| A1 | Pump has run dry. | Check system pressure, add water and bleed system as necessary. |

| A7 | Hot water NTC Sensor defective. | Check hot water NTC sensor and connecting lead for circuit breaks/short circuits. |

| b1 | Code plug not deteched | Insert code plug correctly, test and replace if necessary. |

| C6 | Fan speed too low. | Check fan lead and connector, and fan; replace as necessary. |

| E2 | CH flow NTC Sensor defective. | Check CH flow NTC sensor and connecting lead. |

| E9 | Safety temp. limiter in CH flow has tripped. | Check system pressure,check safety temp. limiters, check pump operation, check fuse on pob, bleed appliance. |

| EA | Flame not detected. | Is gas cook turned on? Check gas supply pressure, power supply, iginiter electrode and lead, ionisation sensing electrode and lead, flue duct and CO2 level. |

| F0 | Internal error | Check electrial connector contacts, programmer interface modeule ignition leads are not loose; replace pcb if necessary. |

| F7 | Flame detected even through appliance switched off. | Check electrode assembly, dry pcb. Flue clear? |

| FA | Flame detected after gas shut off. | Check gas valve and wiring to gas valve. Clean condensation trap and check electrode assembly. Flue clear? |

| Fd | Reset button pressed by mistake. | Press reset button again. |

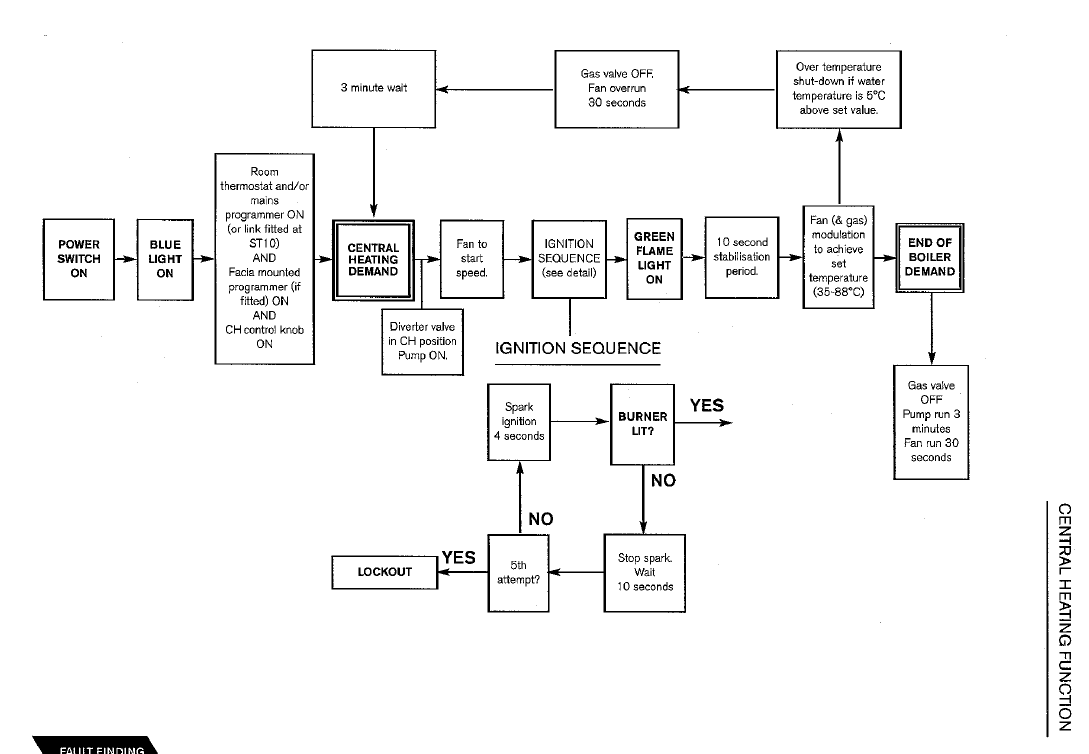

CDi Central Heating Function

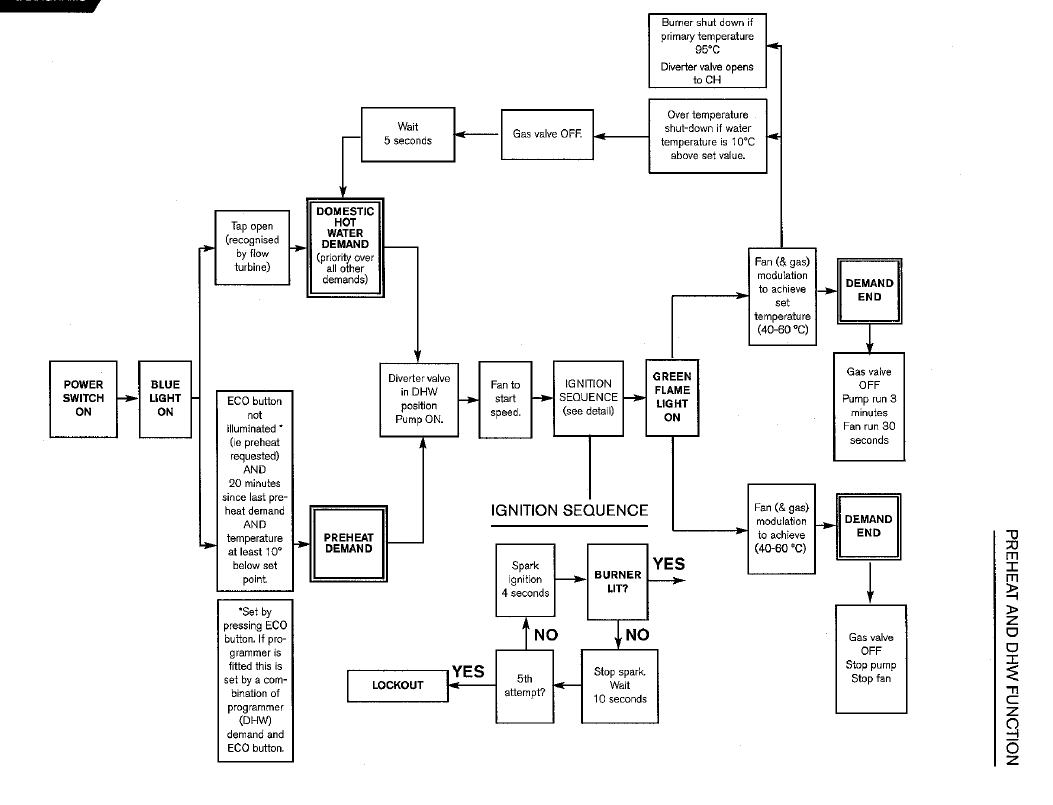

CDi Preheat and DHW Function

Worcester Bosch Highflow 440

Use the Fault Finding table below to diagnose your Worcester Highflow 440 problem to allow you to get your boiler working again.

Highflow 440 Troubleshooting Table

| Display code | Fault Description | Check repair / replace as necessary |

|---|---|---|

| F0 | Internal error | Transformer. |

| All connections to control board. | ||

| Otherwise replace control board. | ||

| F7 | Flame detected with no demand | Gas valve |

| Flame sense electrodes/cables | ||

| Moisture on control board. | ||

| Blocked condonsate trap. | ||

| Otherwise replace control board. | ||

| FA | Flame detected with after gas | Cables and connections to gas valve. |

| Gas valve switched off | Condonsate trap. | |

| Flue (for blockages). | ||

| Otherwise replace control board. | ||

| Fd | Reset button pressed by mistake | Press reset button again. |

| P1,P2,P3,P1 | Please wait , initialisation in progress | Replace fuae S12. |

| Otherwise replace control board. | ||

| No central heating hot water OK | Demand signal from roomset/CH timer (r link fitted at ST4) | |

| CH channel of facia mounted programmar (if fitted). | ||

| CH control knob position. | ||

| No hot water, central heating OK | Flow turbine | |

| Demand signal from DHW timer (for link fitted at ST 8). | ||

| DHW channel of facia mounted programmer (if fitted). | ||

| No functions | 230V fuse (S11). | |

| Transformer. | ||

| Otherwise replace control board.. | ||

| Poor performance / noises | Fan/fan harness. | |

| Sensors not fixed or out of specification. | ||

| Gas pressure / blockage. | ||

| Water pressure / blockage. | ||

| CO2 mix. | ||

| Flue blockage. | ||

| Noisy ignition | Spark electrodes / cables. | |

| Gas valve. | ||

| Gas supply. | ||

| CO2 mix. | ||

| Seals. | ||

| A5 | Tank sensor fault | Tank sensor (8000-20000 ohms at room temperature). |

| Wiring and connections to sensor. | ||

| A7 | DHW sensor fault | DHW sensor (8000-20000 ohms at room temperature). |

| Wiring and connections to sensor. | ||

| A8 | Module fault | Night set black module TR212E and / or Roomstat TR2. |

| Wiring and connections between modules. | ||

| b1 | Code plug not detected | Code plug version , condition and fitting. |

| If OK replace control board. | ||

| C1 | Fan speed too low | Fan harness and connections. |

| Fan. | ||

| Otherwise replace control board. | ||

| d3 | Terminals 8-9 not shorted at connector ST7 | Safety overheat thermostat for underfloor heating system (if fitted). |

| Otherwise fit link. | ||

| d5 | Condensate pump failed | Mains supply to condensate pump. |

| Condensate Pump unit. | ||

| Continuity of all cables to pump unit. | ||

| d6 | Tank overheat | Tank sensor is correctly fixed to tank. |

| Wiring and connections to sensor. | ||

| E2 | CH flow sensor fault | CH flow sensor (8000-20000 ohms at room temperature). |

| Wiring and connections to sensor. | ||

| E9 | Safety overheat device tripped | All air vented. |

| Water pressure above minimum. | ||

| Leaks or blockage. | ||

| Condition and attachment of CH flow sensor. | ||

| Pump and associated wiring /connections. | ||

| Connections and wiring to overheat thermostat devices. | ||

| Otherwise replace control board. | ||

| EA | Flame not detected | Gas present and at correct pressure. |

| Combustion CO2 level. | ||

| Condition of flue. | ||

| Ignition electrodes. | ||

| Ignition harness and connections. | ||

| Flame sense harness. | ||

| Flame sense cables and connections . | ||

| Gas valve. | ||

| Otherwise replace control board. |

Worcester Bosch Heatslave

The Worcester Heatslave troubleshooting tables below will aid you in diagnosing the problem with your boiler. This will allow you to call in a service engineer and purchase the exact replacement parts your need to fix the problem.

Worcester Heatslave Fault Finding Table

| PROBLEM | CAUSE | REMEDY |

|---|---|---|

| LOCKOUT : | ||

| Pulsation on start | CF-Flue draught incorrect | CF-Check flue draught |

| Combustion settings incorrect | Set up as in installation instructions | |

| Faulty nozzle | Replace nozzle | |

| Intermittent lockout | Bad electrical connection | Check control box/electrical connections |

| Intermittent flame detection fault | See flame detection fault | |

| Down draught | Extend flue or fit an anti-downdraught cowl (CF only) | |

| Burner motor fails to operate | Faulty motor electrical supply to motor | Check for 230v at motor plug during startup period |

| Control box fault | Replace control box | |

| Flame detection fault | Photocell filmed over (dirty) | Clean |

| Photocell faulty | Replace | |

| Control box faulty | Replace | |

| Air adjustment fault | Incorrect CO2 | Set up as in installation instructions |

| No oil from nozzle | No oil at pump | Check and refill oil tank/bleed oil line |

| Check and clean filters & valves from oil tank to boiler | ||

| Air in pump | Bleed pump | |

| Nozzle blocked | Replace nozzle | |

| Faulty pump or drive | Replace | |

| Faulty mechanical shut off valve | Clean or replace | |

| Ignition failure | Electrode settings incorrect | Set up as in installation instructions |

| Faulty ignition transformer | Replace | |

| Open circuit ignition | Check and replace electrodes or high tension leads if necessary | |

| Faulty control box or electrical connections not properly made | Correct electrical control box connections or replace control box | |

| BURNER FAILS TO START | No power to boiler | Check electrical / control circuit |

| Faulty boiler thermostat | Check by temporarily linking out high limit and control thermostat | |

| Programmer open circuit | Check by temporarily linking 8 & 9 on the connector | |

| Faulty control box | Replace | |

| HIGH SMOKE NUMBER | Air intake /flue blocked | Check & clear air intake/flue |

| Incorrect combustion settings | Set up as in installation instructions | |

| Oil pressure incorrect | Adjust to correct pressure | |

| Incorrect components used on combusion head | Check with installation instructions | |

| Faulty nozzle | Replace nozzle | |

| FAULTY BOLIER OPERATION : | ||

| Noisy operation | Pump noise from air in pump or worn pump | Bleed air from pump or replace pump |

| Wom motor bearings | Replace motor | |

| Fan out of balance | Replace fan | |

| Boiling | Faulty boiler thermostat | Replace if necessary |

| Short circuit boiler thermostat | Takeout of circuit to check | |

| Thermostat bulb not fully home in pocket | Ensure bulb is pushed fully home | |

| No primary water circulation | Check system/circulating pump | |

| Short Cycling | Burner rating incorrect | Correct burner rating |

| Boiler thermostat differential incorrect | Replace boiler thermostat | |

| External controls not operating correctly | Check and correct external controls | |

| OIL SMELLS | Blocked flue, furnes on startup | CF-Check flue with gauge and seals/gaskets |

| RS-Check seals/gaskets | ||

| Oil soaked boiler, faulty burner operation, numerous lockouts | Rectify burner operation and lockouts | |

| Odour in boiler room, oil leaks from pipework, flexible hoses connections | Rectify oil leaks, replace components if necessary |

Worcester Bosch Greenstar HE

If you have a problem with your Greenstar HE series boiler use the troubleshooting table below to identify the problem.

Worcester Greenstar HE Troubleshooting Table

| Display Code | Description | Remedy |

|---|---|---|

| A7 | Hot water NTC sensor defective | Check hot water NTC sensor and connecting lead for circuit breaks/short circuits. |

| A8 | Break in communication | Check connecting lead to programmer |

| AC | Module not detected. | Check connecting lead between TA211E/TR212E and Heatronic |

| b1 | Code plug not detected. | Insert code plug correctly, test and replace if necessary. |

| C1 | Fan speed too low. | Check fan lead and connector, and fan; replace as necessary. |

| d3 | Jumper 8-9 not detected. | Connector not connected, link missing, underfloor heating limiter tripped. |

| E2 | CH flow NTC sensor defective | Check Ch flow NTC sensor and connecting lead. |

| E9 | Safety temp. limiter in CH flow has tripped. | Check system pressure, check safety temp. limiters, check pump operations, check fuse on pcb, bleed appliance. |

| EA | Flame not detected. | Is gas cock turned on? Check gas supply pressure, power supply, igniter electrode and lead, ionisation sensing electrode and lead, flue duct and CO2 level. |

| F0 | Internal error. | Check electrical connector contacts, programmer interface module iginition leads are not loose; replace pcb if necessary. |

| F7 | Flame detected even though appliance switched off. | Check electrode assembly, dry pcb. Flue clear? |

| FA | Flame detected after gas shut off. | Check gas valve and wiring to gas valve. Clean condensation trap and check electrode assembly.Flue clear? |

| Fd | Reset button pressed by mistake. | Press reset button again |

| P1,P2,P3,P1 | Please wait, initalisation in progress | 24 V fuse blown. Replace fuse. |

Worcester Bosch Greenstar Utility

Check out the Worcester Greenstar Utility fault finding tables below to diagnose your boiler’s issue. Follow the table from top to bottom to help you identify the issue then you can find the corresponding replacement part.

Worcester Greenstar Utility Fault Finding Table

| PROBLEM | CAUSE | REMEDY |

|---|---|---|

| FAULTY BOLIER OPERATION : | ||

| Noisy operation | Pump noise from air in pump or worn pump | Bleed air from pump or replace pump |

| Wom motor bearings | Replace motor | |

| Fan out of balance | Replace fan | |

| Boiling | Faulty boiler thermostat | Replace if necessary |

| Short circuit boiler thermostat | Takeout of circuit to check | |

| Thermostat bulb not fully home in pocket | Ensure bulb is pushed fully home | |

| No primary water circulation | Check system/circulating pump | |

| Short Cycling | Burner rating incorrect | Correct burner rating |

| Boiler thermostat differential incorrect | Replace boiler thermostat | |

| External controls not operating correctly | Check and correct external controls | |

| OIL SMELLS | Blocked flue, furnes on startup | CF-Check flue with gauge and seals/gaskets |

| RS-Check seals/gaskets | ||

| Oil soaked boiler, faulty burner operation, numerous lockouts | Rectify burner operation and lockouts | |

| Odour in boiler room, oil leaks from pipework, flexible hoses connections | Rectify oil leaks, replace components if necessary |

Worcester Bosch Danesmoor Regular, Utility, System, WM and FS

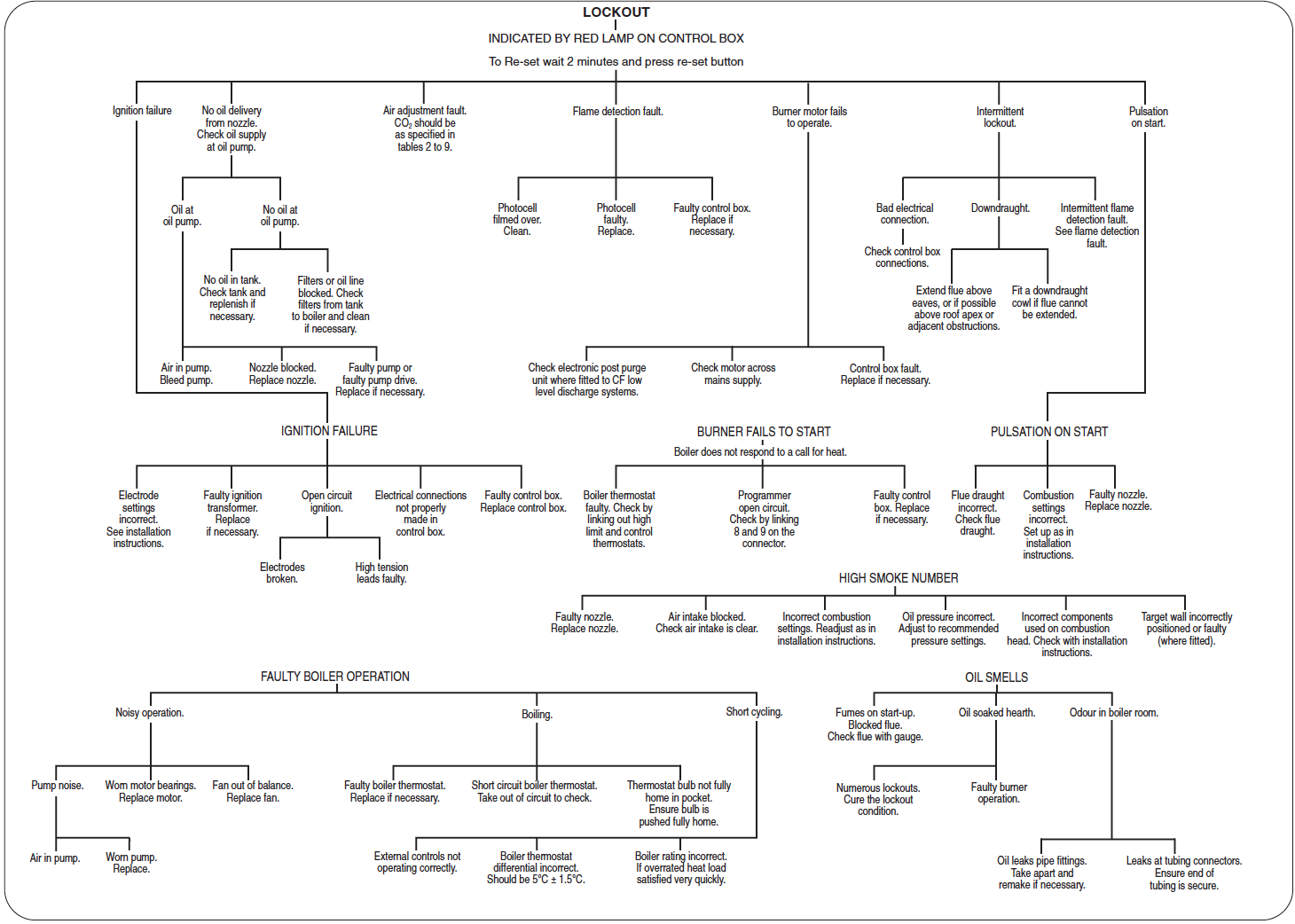

The Worcester Danesmoor series of boilers covers a wide range of quality boilers offered by the company. To fault find any issues with this range follow our fault finding chart or troubleshooting tables below.

Troubleshooting Table

| PROBLEM | CAUSE | REMEDY |

|---|---|---|

| LOCKOUT: | ||

| Pulsation on start | CF - Flue draught incorrect | CF - Check flue draught |

| Combustion settings incorrect | Set up as in installation instructions | |

| Faulty nozzle | Replace nozzle | |

| Intermittent lockout | Bad electrical connection | Check Control box/electrical connections |

| Intermittent flame detection fault | See flame detection Fault | |

| Downdraught | Extent flue or fit a downdraught cowl | |

| Burner motor fails to operate | Faulty motor or electrical supply to motor | Check for 230v at motor plug during startup period |

| Control box fault | Replace control box | |

| Flame detection fault | Photocell filmed over (dirty) | Clean |

| Photocell faulty | Repalce | |

| Control box fault | Repalce | |

| Air adjustment fault | incorrect CO2 | Set up as in installation instructions |

| No oil from nozzle | No oil at pump | Check and refill oil tan |

| Check and clean filters & valves from oil tank to boiler | ||

| Air in pump | Bleed pump | |

| Nozzle blocked | Replace nozzle | |

| Faulty pump or drive | Repalce | |

| Faulty mechanical shut off valve | Clean or replace | |

| Ignition failure | Electrode settings incorrect | Set up as in installation instructions |

| Faulty ignition transformer | Replace | |

| Open circuit ignition | Check and repalce electrodes or high tension leads if necessary | |

| Faulty control box or electrical connections not properly made | Correct electrical control box connections or replace control box | |

| BURNER FAILS TO START | No power to boiler | Check electrical / control circuit |

| Faulty boiler thermostat | Check by temporarily linking out high limit and control thermostats | |

| Programmer open circuit | Check by linking 8 & 9 on the connector | |

| Faulty control box | Replace | |

| HIGH SMOKE NUMBER | Air/flue intake blocked | Check & clear air/flue intake |

| Incorrect combustion settings | Set up as in installation instructions | |

| Oil pressure incorrect | Adjust to correct pressure | |

| Incorrect components used on combustion head | Check with installation instructions | |

| Faulty nozzle | Replace nozzle | |

| FAULTY BOILER OPERATION: | ||

| Noise operation | Pump noise from air in pump or wom pump | Bleed air from pump or replace pump |

| Worn motor bearings | Replace motor | |

| Fan out of balance | Repalce fan | |

| Boiling | Faulty boiler thermostat | Replace if neccesary |

| Short circuit boiler thermostat | Take out of circuit to check | |

| Thermostat bulb not fully home in pocket | Ensure bulb is pushed fully home | |

| No primary water circulation | Check System / circulating pump | |

| Short Cycling | Burner rating incorrect | Correct burner rating |

| Boiler thermostat differential incorrect | Replace boiler thermostat | |

| External controls not operating correctly | Check and correct external controls |

Fault Finding Chart